Sumitomo Drive Technologies presents new Condition Monitoring System at SPS 2023

The eye series combines real-time drive monitoring with oil filtration

Markt Indersdorf (Germany), October 12, 2023

Detecting damage before it occurs is the key to success in modern machine maintenance. Against this backdrop, Sumitomo Drive Technologies will be showcasing its eye series at SPS 2023 from November 14 to 16 in Nuremberg, Germany: eye CLEAN, eye CONNECT, and eye COMPLETE. Visitors can learn all about the new Condition Monitoring System (CMS) for drive solutions at Hall 3, Booth 364.

The machinery manufacturer's CMS innovation goes one step further than existing systems by combining drive condition monitoring with oil filtration in an all-in-one solution. With predictive maintenance, users increase the reliability and service life of their machinery and systems.

Other highlights of the booth that Sumitomo Drive Technologies is sharing with Lafert Group and Invertek Drives are the new generation of ECY precision gears featuring enhanced performance and a flexible motor adapter system for the seamless integration of servo motors, and the drive solutions for robotics and Industry 4.0. These include the TUAKA actuator series, a fully integrated drive for robots and cobots, as well as Smartris, a drive solution (consisting of gear, servo motor, and drive) for automated guided vehicle (AGV) systems and autonomous mobile robots (AMRs). Visitors will also have the chance to try out the cycloidal, or Cyclo, principle on an interactive model. The cycloidal principle was invented almost 100 years ago by German engineer Lorenz Braren. The company that Braren established was later acquired by Sumitomo and the Cyclo principle continues to provide the basis for Sumitomo Drive Technologies' key products and to form the cornerstone of its reputation as a technology leader to this day.

Predictive maintenance combined with oil filtration

Bringing together Sumitomo Drive Technologies' decades of know-how in drive solutions with the Industrial Internet of Things (IIoT), eye COMPLETE is a CMS that allows users to analyse the condition of their systems and machinery in real time while also maintaining the gear oil.

The wide range of features including advanced vibration monitoring, oil analysis, and oil filtration contribute to predictive maintenance, thereby increasing the reliability and service life of machinery and systems. For vibration monitoring, the CMS provides sophisticated yet user-friendly data processing. The eye series ensures quality control of gear oil by taking high-precision measurements of ISO cleanliness levels, water content, and oil temperature.

The eye series consists of three products:

Eye clean

With a filtration capacity of up to 16 litres per minute, this mobile oil filter configuration is ready to be used on site, and can filter both saturated water and oxidized oil. This means that the oil life is potentially up to five times longer.

Eye connect

With its two independent dashboards (one local and one cloud-based), the CMS provides real-time data and insights anywhere and at any moment into gear function, including wear, water content, particles, oil quality, temperature, and vibration.

Eye complete

This combined solution seamlessly integrates machinery condition analysis and oil filtration. With its early-warning technology, eye helps to proactively prevent damage and extend the service life of the machinery.

"Our eye CMS not only supplies information about the current condition of the machinery and its oil – it also predicts exactly when a component failure will occur. These precise predictions are key to optimizing the service life and performance of machinery and systems," says Reza Golafshan, Team Leader Condition Monitoring Systems at Sumitomo Drive Technologies.

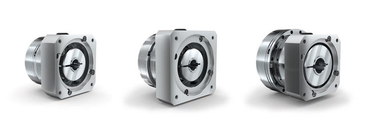

New generation of precision gears to première at SPS

Sumitomo Drive Technologies will also be presenting the new generation of its E CYCLO (ECY) precision gear series at SPS 2023. These high-precision shaft gears are used, for example, for surface machining in dental technology, the semiconductor industry, machine tools, or cobots. Thanks to their internal cylindrical roller bearings, the gear units provide both high rigidity and high performance in a small design envelope. With this new generation, Sumitomo Drive Technologies has once again significantly increased the torque density of the gears, delivering a 30% increase in performance levels in comparison with previous models.

The flexibility of the ECY gears has also been upgraded: they can now be fitted to any motor by means of a modular connection system via Plug & Play. The user benefits from a highly compact performance package that is ready for use. Sumitomo Drive Technologies has also extended this modular plug & play approach to the Fine Cyclo DA and UA series gears.

"Flexibility and short delivery times are invaluable in today's fast-moving industry," says Michael Berger, Product Manager Motion Control Drives at Sumitomo Drive Technologies. "That's why we've equipped the new generation of ECY shaft gear units with an innovative modular connection system. This means that our customers can fit the gears to virtually any motor directly at the factory, for a true Plug & Play experience."

Complete drive solutions for robotics and Industry 4.0

At the booth, visitors can also experience the performance of the TUAKA actuator series for themselves by guiding a robot arm with an integrated torque sensor. TUAKA is a fully integrated drive for robots and cobots that won the prestigious Hermes Award last year. The drive solutions can be configured modularly and with high-resolution encoders, integrated torque sensor, or extended safety functions.

Another highlight awaiting visitors to the SPS is a new, more compact version of the Smartris drive solution for AGVs and AMRs. The Smartris Drive Compact is a compact drive around the size of a computer mouse. Compact AGVs and AMRs can manoeuvre flexibly in settings such as production plants, warehouses, and distribution centres.

Hands-on with the cycloidal principle

For those interested, Hall 3, Booth 364 will also offer the chance to experience and understand the Cyclo principle first hand by trying it out on a model.

Cycloidal gear mechanisms seem complex at first glance, but their design is actually remarkably straightforward: they are eccentric gears without gear wheels. A motor drives the input shaft holding an eccentric bearing. As the eccentric rotates, it rolls the cam discs along the inner circumference of the fixed pin ring. The resulting movement is similar to that of a disc rotating within a ring. As a result, cam sections engage one after the other in the pins of the pin ring and thus give rise to a rotation in the opposite direction at reduced speed. The reduced rotary motion of the cams is transmitted to the output shaft via pins that engage in the holes of the cams. This functional principle enables a high level of torque complementing smooth and vibration-free operation.

The groundbreaking Cyclo principle originated with German inventor and designer Lorenz Braren in the early 20th century. In 1938, Braren entered into a technical alliance with Sumitomo, one of Japan's oldest and largest economic consortiums, which eventually acquired his Munich-based company in the early 1990s. Sumitomo Drive Technologies is thus the pioneer in cycloidal technology and has developed various cutting-edge products over almost a century of corporate history: from compact and reliable precision gears to industrial gears and complete drive solutions.