Desolventizing - Toasting - Cooling - Drying

our Hansen P4 is designed for it

Whether Desolventiser Toaster (DT), Dryer Cooler (DC) or Combined (DTDC) drives, we cater for best in class industrial gear units for our global customer base.

We match the drive to the demanding toaster application and offer enhanced reliability under the most severe conditions.

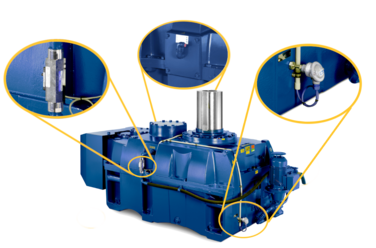

Our Hansen P4 gearbox - Specialized for toaster applications

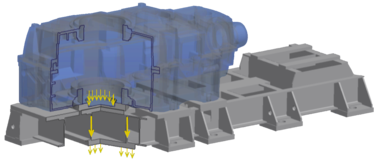

Dedicated vertical housing, robust bearing arrangement and supporting structures

Dedicated vertical P4 housings with robust toaster bearing arrangement are specifically selected to handle the high thrust loads typical for this application. The housings have enlarged mounting pads as a standard and if required, the surface will be increased even further by machining the low-speed shaft’s bottom bearing cover to be on the same plane as the mounting feet. This maximizes the surface, which is supported by the mounting chassis, to avoid excessive stresses in the gear unit housing. Furthermore, the chassis (base plate) will be constructed by us so that forces are guided directly to the foundations.

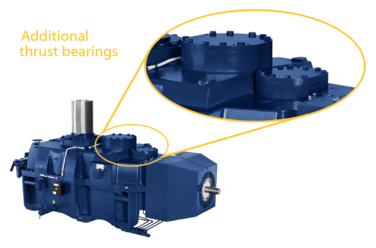

Additional bearing arrangement for enhanced robustness

Based on detailed technical investigations and in close cooperation with our customers we developed a new bearing arrangement to further enhance the robustness of our toaster drives. This recommended arrangement includes additional thrust bearings on the intermediate shafts, ensuring the axial and radial forces to be accommodated by two separate bearings. As a result the load distribution over the rollers is optimized, thereby making this bearing arrangement more capable of handling transient loads, typical for desolventiser toaster drives.

This optional bearing arrangement is also available as an ‘upgrade kit’ for installed units.

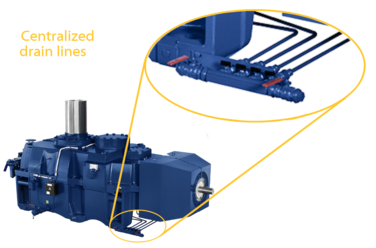

Anti-humidity breather filter, Labyrinth seals and drain lines for condensation of bearings

Protecting the gear unit’s internals from moisture and condensation is vital to ensure long trouble-free operation, therefore we supply every Hansen P4 toaster drive standard with the appropriate solutions for this heavy duty application.

P4 toaster drives are standard delivered with regreasable labyrinth sealing at the input and output shaft and a silicagel breather filter to have high resistance in extreme humidity environments,

As even these precautions can not totally avoid condensation in the gear unit, drain lines are fitted at each bottom bearing cover, also facilitating taking oil samples per bottom bearing.

Reduced downtime due to reliability and easy maintenance

Reliability is crucial as Toaster drives are located at the heart of the process and need to operate continuously. Any downtime in the process may have consequences on plant profitability far in excess of the original equipment cost. Hansen P4 toaster gear units are standard provided with an oil flow- and oil level switch. Optionally, condition monitoring systems can be added for real time monitoring of Oil Contamination, Temperature and vibration analysis.

Furthermore, every Hansen P4 gear unit is standard provided with a large inspection cover above the oil level and with the O-sealing it is easy to open/close for inspection and service on-the-spot. If even this is not enough, thanks to the Hansen P4 split plane housing - horizontally positioned and also fully above the oil level - a full inspection and maintenance is possible with a minimum of effort.

Explosive atmospheres

Desolventiser toasters most often operate in potentially explosive atmospheres. We can offer complete drives compliant with European (ATEX) standards, CE or UKCA product marking.

References

Our long history of solid partnerships with world-class OEM's and many end-users make us the preferable partner when it comes to desolventizing, drying, toasting and cooling.