Sumitomo Drive Technologies Presents Drive Solutions at Mountain Planet 2024

Decades of experience and the Cyclo principle signify robustness and long lifespan

Serris (France) / Markt Indersdorf (Germany), April 10, 2024

Sumitomo Drive Technologies will showcase to international mountain professionals at the Mountain Planet exhibition from April 16 to 18, 2024, in Grenoble, France, in Hall 3, Booth 321. As an expert in drive technology for various industries, Sumitomo Drive Technologies will present its robust and reliable drive solutions for ropeway transport at the exhibition.

Ropeway transports are crucial for the smooth operation of ski resorts and must, therefore, be extremely reliable to avoid costly failures and operational disruptions. With decades of experience in the development and manufacturing of drive systems, Sumitomo Drive Technologies offers customized solutions that meet the demanding requirements of the ropeway industry.

Reducing operating costs and addressing sustainability goals

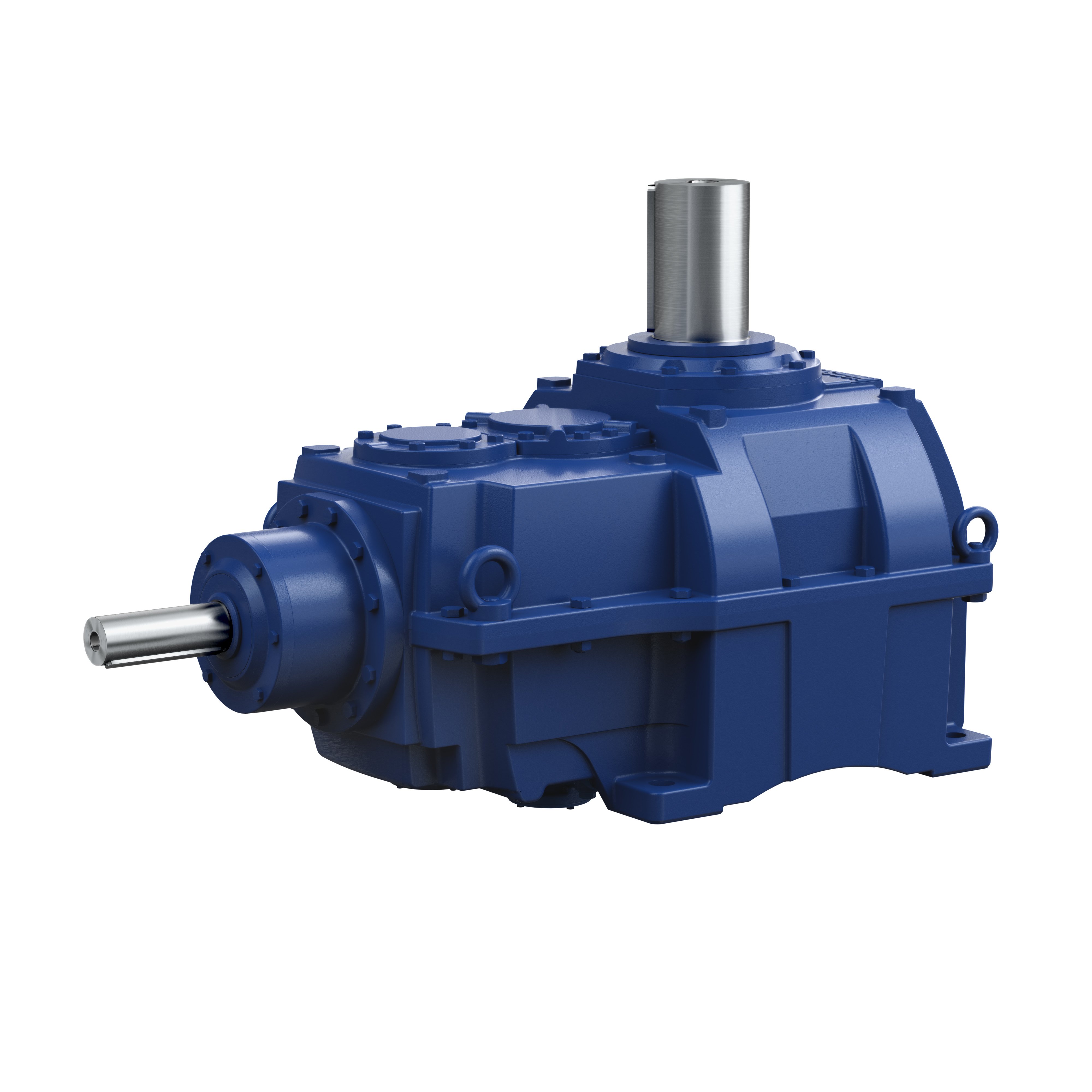

Visitors to the Mountain Planet exhibition will have the opportunity to see a Hansen P4 speed reducer for vertical applications at the booth. With our division Hansen Industrial Transmissions NV (HIT) located in Edegem, Belgium, Sumitomo Drive Technologies has a century of innovative technologies and expertise. HIT celebrated its 100th anniversary last year.

Hansen P4 vertical shaft reducers are the best solutions in many applications, not only for reducing ongoing operating costs but also for being environmentally friendly. Due to their special design, these speed reducers consume less electrical energy and less lubricant.

With 20 different sizes and nominal torques ranging from 3 to 1100 kNm, the Hansen P4 gearbox series offers great versatility and performance. Integrated and reinforced bearings ensure a robust construction that withstands high axial and radial loads. Symmetrically located mounting feet around the output shaft ensure uniform force distribution and increase system stability.

"Cyclo Drive 6000," a classic symbol of reliability

Visitors at the booth will also have the opportunity to inspect a cutaway model of the Cyclo Drive 6000 gear motor. The Cyclo Drive 6000 is the most widely used gear motor from Sumitomo Drive Technologies and a classic for driving ropeway transports. Thanks to its Cyclo gear principle, invented by the company, the Cyclo Drive 6000 is characterized by maximum robustness and reliability. The Cyclo principle ensures high durability and a long lifespan.

On-site services and expertise

At its booth, Sumitomo Drive Technologies also provides information on its service offerings, both for its own reducers (with and without cycloidal principle) and for those of other manufacturers. On-site inspection services allow for pre-checking the condition of the transmission and its environment to eliminate any defects during the season and ensure optimal operation. On-site repair of equipment helps to minimize downtime of installations and overall repair costs. Sumitomo Drive Technologies experts also offer basic training for ski resort employees so that they can troubleshoot quickly during the season.

For modern machine maintenance, Sumitomo Drive Technologies has developed its own condition monitoring system. The eye series goes a step further than existing systems by combining drive condition monitoring with oil filtration in one solution. With proactive maintenance, users increase the reliability and lifespan of their machines and installations.