Overview

24/7 MONITORING

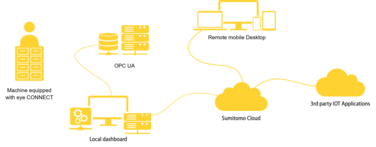

Realtime data insights any time, any place

24/7 analyses of parameters to ensure correct function of gearbox

- Online oil ISO 4406 Cleanliness Level

- Wear particles

- Oil humidity level

- Oil cross contamination

- Oil temperature

- Advanced vibration analysis including FFT analysis and KPI monitoring

Data securely stored in the cloud behind passwords.

Overview of alarms.

Plug & Play including all sensors.

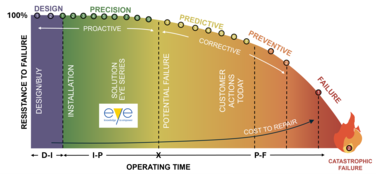

eye not only provides information about the current status of the machine and its oil, but also accurately predicts when a component will fail..

These precise predictions are crucial for optimizing the lifespan and performance of machinery and equipment.

eye CONNECT monitors following important parameters 24/7

Oil temperature

Water saturation

Wear development

Advanced vibration analysis

D-I-P-F CURVE

(Design - Installation - Potential Failure - Failure)

Equipped with connection standard

GPRS + SIM

WIFI

LAN

Working Principle

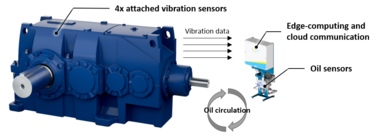

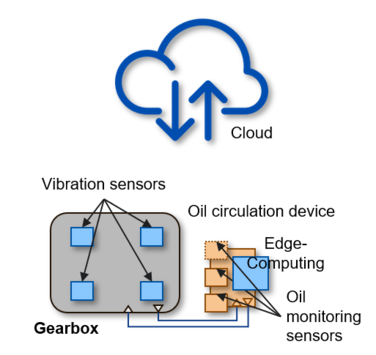

4 vibration’s sensors

Frequency and time domain vibration data

Analogue inputs for monitoring further measurement variables

Using advanced frequency domain KPIs, reliable vibration monitoring of machine components

24/7 monitoring of important events by oil quality and vibration data KPIs

Spare parts and accessories

Ethernet cable, IP67

- 3 m

- 6 m

- 6 m

Power cord, IP67

- 3 m

- 5 m

- 5 m

Vibration sensor, including cable

- 5 m

- 10 m

- 10 m

Hose including 1 1/2 inch coupling

- 1/2 inch

- 3/4 inch

- 1 inch

- 1 1/2 inch

- 2 inch

- 3/4 inch

- 1 inch

- 1 1/2 inch

- 2 inch

Viton sealkit

Protection (spin-on) filter

- 125 µm