E CYCLO – ECY

Shaft gear units with high rigidity for use in the smallest installation spaces

Overview

High precision shaft gear with output flange and high rigidity

The new E CYCLO series features high rigidity due to its internal roller bearings. This is significantly higher when compared to the competition. Therefore, the E CYCLO can achieve higher performance in a smaller design envelope and thus lower costs.

- High Rigidity

- Lost Motion 1.0 arcmin

- Transmission error 0.75 arcmin

- Maximum drive speed up to 8500 rpm

- Permissible torques up to 284 Nm

- Radial loads up to 2050 N

- Axial loads up to 3000 N

- Completely sealed including cross roller main bearing

| No mechanical backlash | |

| Lost Motion | 1.0 arcmin |

| Sizes | 3 |

| Reduction ratios | 50:1 to 100:1 (selectable in all sizes) |

| Nominal output torque | 30 - 96 Nm |

| Acceleration torque | 44 - 157 Nm |

| Peak torque for emergency stop | 91 - 284 Nm |

| Output speed | up to 170 rpm |

| Max. axial load | 385 - 483 N |

| Torsional stiffness | up to 15.9 Nm/arcmin |

Key Product Facts

Out of the box motor and adapter for each size

Maximum flexibility for any motor

Advantages of the Fine Cyclo E Cyclo Series

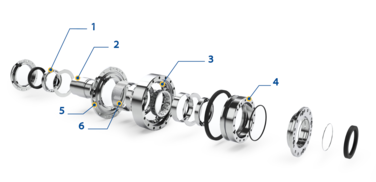

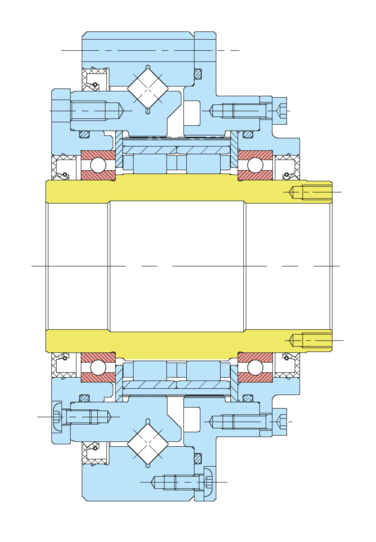

E Cyclo (ECY) - Highlights in detail

1) Bearing for high speed shaft

2) Eccentric high speed shaft

3) Main bearing (cross roller)

4) Output ring gear housing

5) Ring gear housing

6) Cycloid spline

E Cyclo, the smallest units from Sumitomo. With these units we provide a highly precise, compact and powerful unit to fulfil your needs.

In addition the gear can perform a higher tilting stiffnesses than comparable units on the market. An integration in narrow applications becomes easy.

To be most flexible we also provide individual motor flanges to realise a connection to your desired motor.

Gear technology

The teeth profile was developed in our R&D department from scratch. The profile enables a performance with highest standards and a long-lasting operation.

This unique reducer structure by using a profile with epitrochoid parallel curves is being used in industrial robots and transfer devices all over the world.

The ECY series, which was developed as a compact reducer for non-backlash applications, fuses the strain wave gear with the engagement theory of the CYCLO Drives, thus realizing high rigidity and a compact structure that were unavailable until now.

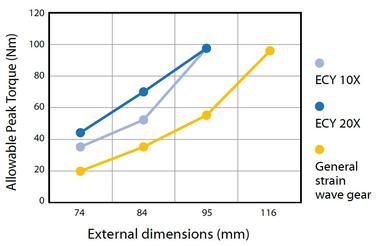

High peak torque

The allowable peak torque is up to 1.5 times higher that a comparable strain wave gear of equivalent size.

This performance density enables the device to be miniaturized.

In addition, the units are cost efficient and flexible in the field of operation.

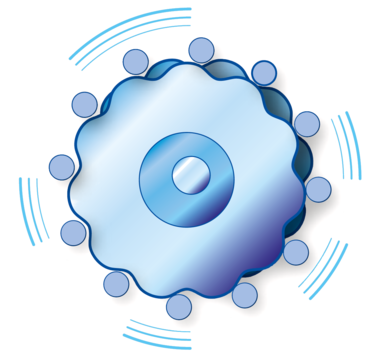

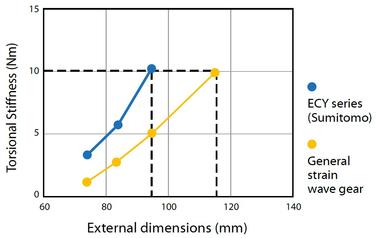

High tortional stiffness

The tortional stiffness is approximately twice as high as a comparable strain wave gear of equivalent size.

This characteristic enables the strength of the device to be increased and vibration to be reduced.

The units provide a high precision and reduce interference to a minimum.

Especially for highly precise, repeating applications the design guarantees a constant and reliable result.

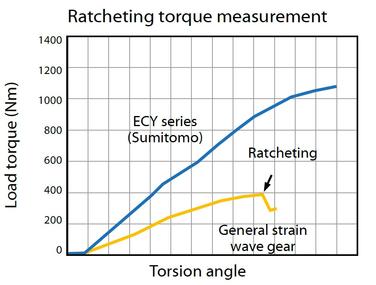

High rigidity

According to the design the units do provide a high rigidity and so prevent the teeth from ratcheting.

Operation becomes secure and prevent the application from overload. Even in the case of overload the units still ensure full functionality and a save operation.

This makes E Cyclo gears the perfect choice for safety relevant or collaborative applications.

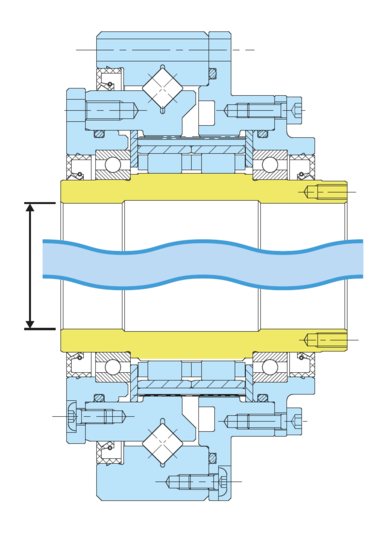

Big hollow shaft for ultimate flexibility

Despite the compactness the hollow shaft is designed with a big diameter. In the application supply cables for cooling, power or data acquisition can be guided through the unit easily.

The hollow shaft is the precondition to realise clean-room applications and robotic applications without external cables.

Coupling with a servo motor is easy, already tested and evaluated in real conditions.

Easy assembly

E Cylco units are fully sealed and ready to use. The full sealed conditions allow the unit to be operated in any position without additional modifications.

The existing construction elements ensure an easy and fast integration with motors and the application.

With the already built in main bearing installation and integration becomes time and cost efficient.

E Cyclo in Motion

Main dimensions and mass

| Size | Length L [mm] | Diameter G [mm] | Diameter D [mm] | Diameter d1 max. () [mm] | Mass[kg] |

|---|---|---|---|---|---|

| 203 | 52.5 | 74 | 54 | 19 | 0.9 |

| 205 | 56 | 84 | 64 | 21 | 1.2 |

| 107 | 58 | 95 | 72 | 25.5 | 1.6 |

Diameter G = Casing diameter

Diameter D = Output major diameter

Diameter d1 = Input shaft diameter

(1) maximum values, adjusted to customer motor

Torque and Speed main data

| Size | Nominal output torque [Nm] up to | Accel.- /decel. Torque [Nm] up to | Max output speed [rpm] | |

|---|---|---|---|---|

| 203 | 44 | 70 | 170 | |

| 205 | 75 | 107 | 146 | |

| 107 | 96 | 157 | 130 | |

Output bearing capacity

| Size | Max permissible axial load push/pull [N] |

|---|---|

| 203 | 1,590 |

| 205 | 1,590 |

| 107 | 3,000 |

Available ratios

| Size | Ratios |

|---|---|

| 203 | 50 / 80 / 100 |

| 205 | 50 / 80 / 100 |

| 107 | 50 / 80 / 100 |

Above technical specifications are intended for rough preselection only.