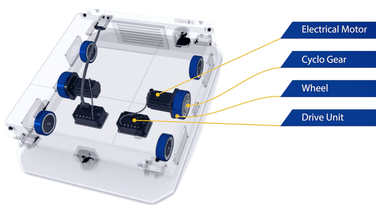

smartris - Packaged-Drive Solution for AGV/AMR

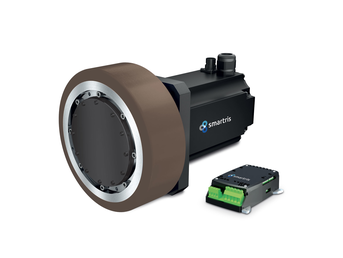

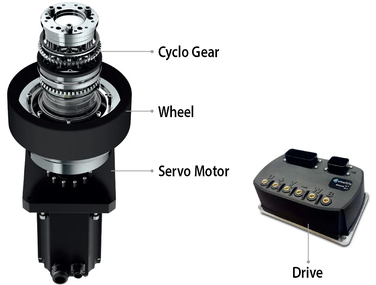

Combination of three smart components. \n A compact, integrated, and intelligent solution of : Gear + Servo Motor + Drive.

Complete Package Solution of Gear, Servo Motor and Drive

- Best fit for AGV or AMR driving

- Compact size achieved by in-wheel structure

- Easy installation and commissioning

- Filled with long-life grease (when shipped from factory)

- Maintenance free

- Customization available on request

| Type | ECO(S, M) / PRO(M, L) |

| Reduction Ratio | ECO: 21-29 / PRO: 22-30 |

| Output Type | Gear Output Shaft Rotation / Ring Gear Housing Rotation |

| Brake | PM(Permanent Magnet) Brake , Spring Brake |

| Feedback sensor | Resolver, Absolute Encoder, Safety Absolute Encoder |

| Safety Function | with STO(Safe Torque Off), without STO |

Key Customer Benefits

Servo Motor & Gear

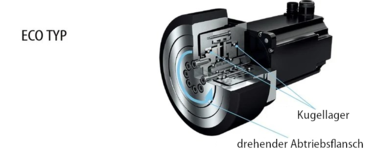

ECO Line

- Gear Output Shaft Rotation Design

- Cost efficient

- Ideal for light payloads and high-speed AGV

PRO Line

- Ring Gear Housing Rotation Design

- High radial loads

- Reduced overall dimension

Drive

- Easy installation without additional PID tuning

- Easy to install with state machine profile suitable for all AGVs

- Specifically designed for prompt reaction in case of AGV emergency quick stop

Smartris installation example

Reasons for choosing smartris

Packaged-Drive Solution

Three key components: gear, servo motor and drive in one package. It provides a highly reliable solution for various types of AGV/AMRs.

Support a wide range of performance

Multiple sizes and reduction ratios are available. The optimum product can meet wide variety of AGV/AMR’s specifications; total weight (payload + body weight) and max speed.

Variety of control modes

Speed control, position control and torque control are supported. These three control modes enable high-precision control.

Global Supply Chain

We provide high quality products to the global market by utilizing our manufacturing facilities around the world.

smartris Drive Compact

The new super-compact drive for AGV and AMR applications is four times smaller than the standard drive and is suitable for our ECO-S line. This makes it the perfect solution for companies that want to optimise the space requirements of their AGVs and AMRs without compromising on performance.

Gearmotor (Gear + Servo Motor)

Specifications

| Type | ECO | PRO | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | S | M | M | L | |||||||

| Voltage [VDC] | 48 | 48 | |||||||||

| Allowable Radial Load per Driving Wheel [N] | 1500 | 3000 | 6500 | 10000 | |||||||

| Reduction Ratio | 21 | 25 | 29 | 21 | 25 | 29 | 22 | 26 | 22 | 26 | 30 |

| Max Motor Speed [r/min] | 4500 | 4500 | 4500 | 3000 | |||||||

| Max Wheel Speed [r/min] | 214 | 180 | 155 | 214 | 180 | 155 | 205 | 173 | 136 | 115 | 100 |

| Rated Wheel Torque [N·m] | 16.0 | 18.9 | 18.9 | 39.3 | 40.4 | 40.5 | 39.3 | 40.4 | 84.7 | 87.5 | 80.3 |

| Peak Wheel Torque (2sec) [N·m] | 61.9 | 73.7 | 84.8 | 145 | 179 | 207 | 145 | 179 | 294 | 360 | 246 |

| Ambient Temperature [°C] | - 10 to 40 | - 10 to 40 | |||||||||

| Protection Class | IP54 (IP65) | IP54 (IP65) | |||||||||

| Thermal Class | Motor : 155 (F), Brake : F | Motor : 155 (F), Brake : F | |||||||||

| Output Type | Output Shaft Rotation | Ring Gear Housing Rotation | |||||||||

Note:

1. Allowable radial load of ECO type is a value at the position inside the output shaft end face.

2. Allowable radial load of PRO type is a value at the center of the gear part.

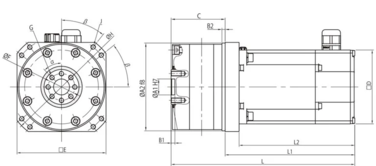

Dimensions

| Type | Size | L | L1 |

L2 |

ØA1 | ØA2 | B1 | B2 | C | □D | □E | ØF | G | ØH | J | K | ØN | M | α° | β° |

Mass [Kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ECO | S | (*) | (*) | (*) | 25 | 110 | 6 | 4 | 76 | 80 | 110 | 35 | 10-M6 | 130 | 4-M8 | - | - | - | 36 | 45 | 5.6 |

| M | 289 | 204 | 182 | 25 | 138 | 6 | 5 | 85 | 116 | 140 | 42 | 8-M8 | 160 | 8-M8 | - | - | - | 45 | 38.5 | 11.3 | |

| PRO | M | 282.5 | 199 | 182 | 145 | 123 | 27.5 | - | 28 | 116 | 160 | 134 | 4-M10 | 190 | 4-M10 | 4.1 | 140 | 23.5 | 30 | 45 | 14.5 |

| L | 309 | 213 | 196 | 182 | 155 | 38 | - | 30 | 142 | 196 | 170 | 4-M12 | 230 | 4-M12 | 4.78 | 175.8 | 32.8 | 30 | 45 | 24.5 |

Note:

1. The above dimensions are for the unit with PM brake.

2. (*) = The dimensions vary depending on the configuration of feedback sensor.

Resolver: L=235, L1=159, L2=143

Absolute encoder: L=249, L1=173, L2=157

3. Please inquire us for dimensions other than those listed above.

Drive

Specifications

| Type | ECO | PRO | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | S | M | M | L | |||||||

| Voltage [VDC] | 48 (30 to 60) | ||||||||||

| Rated Current [Arms] | 11.5 | 25.8 | 25.8 | 35.8 | |||||||

| Peak Current (2sec) [Arms] | 41.7 | 96.3 | 96.3 | 136.2 | |||||||

| Peak Current (10sec) [Arms] | 24.9 | 57.5 | 57.5 | 81.3 | |||||||

| Feedback sensor | Resolver, Absolute encoder, Safety absolute encoder | ||||||||||

| Communication Method | CANopen, Modbus | ||||||||||

| Digital Input | 4 Points/photocoupler (24V±20% 100mA) can be used with sink logic or source logic | ||||||||||

| Digital Output | 4 Points/photocoupler (24V±20% 7mA input impedance 3kΩ) can be used with sink logic or source logic | ||||||||||

| Analog Input | 1 point/±10V or 0 to10V (input impedance 10kΩ) | ||||||||||

| Analog Output | 1 point/0 to 10V max 1mA | ||||||||||

| Safety Function | with STO, without STO | ||||||||||

| Protection Class | IP54 | ||||||||||

| Certification | CE + UL | ||||||||||

Note:

1. (*) = We are planning We are planning conformity to Modbus LTU. Please inquire us about RS-232C for service tool.

2. Power cable and control cable are not attached.

Dimensions

Standard Configuration

| Standard Configuration | Other Option | ||||||

|---|---|---|---|---|---|---|---|

| EMEIA | Asia | ||||||

| Feedback sensor | Safety absolute encoder | Resolver | Absolute encoder, Incremental encoder | ||||

| Motor Cable (Power) | IP54 (1m) | IP64 (1m) | |||||

| Motor Connector (Power) | without | IP65 connection | |||||

| Brake | PM brake | Spring brake | |||||

| Safety Function | with STO | without STO | - | ||||