Fine Cyclo DA-Series

Gears with high precision and the highest torque density in a single stage

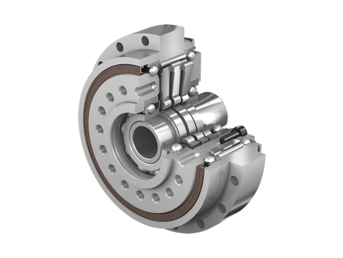

Angular contact ball bearings integrated directly into the gearbox housing.

The improved design provides very accurate motion quality with increased torque density and bearing capacity.

- Highest torque density of our single stage gearboxes

- Ideal for robotic and machine tool applications

- Fully sealed modular design available with motor adapter and clamping ring

| Zero Mechanical Backlash | |

| Lost Motion | <1 arcmin |

| Number of Sizes | 6 |

| Reduction Ratios | 29:1 / 41:1 / 59:1 / 89:1 / 119:1 (availability depending on size) |

| Nominal Torque | 257 Nm up to 1,686 Nm (at n1 = 1,500 rpm) |

| Acceleration Torque | 613 Nm up to 4,000 Nm |

| Max. Momentary Peak Torque | 1,225 Nm up to 8,000 Nm |

| Input Speed | up to 6,150 rpm |

| Max. Bending Moment | 883 Nm up to 4,000 Nm |

| Bending Stiffness | up to 2,450 Nm/arcmin |

| Max. Axial Load | 3,924 N up to 15,000 N |

| Torsional Stiffness | up to 540 Nm/arcmin |

Key Product Facts

4000

Nm

Acceleration Torque

540

Nm

Torsional Stiffness

8000

Nm

Max. Peak Torque

Advantages of Fine Cyclo DA-Series

Ultra compact design

Approx. 8% smaller in diameter and >5% shorter in length and 25% high torque

Great price advantage

Use of the single-stage DA gearboxes results in significant cost advantages compared to available two-stage gearboxes of the identical torque class

Noise levels optimised and significantly reduced

Important factor when people are working near the drive applications, as for example in the medical field.

Easy installation in application

Connection geometry does not require a complex installation, nor does it require an adjustment of the drive shaft

Fully flexible design

Connection of several motor shaft diameters is possible, allowing the use of motors from many different manufacturers

Fully sealed version

Lifetime lubricated ex works

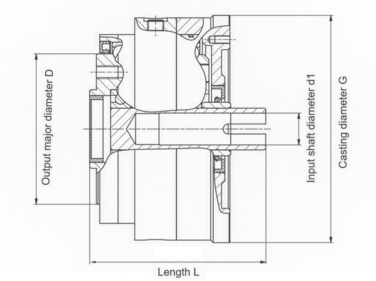

Main dimensions and mass

| Size | Length L (1) [mm] | Diameter G [mm] | Diameter D [mm] | Diameter d1 (2) [mm] | Mass (3) [kg] |

|---|---|---|---|---|---|

| DA15 | 105.5 | 136 | 90 | 19 | 6.4 |

| DA25 | 119 | 159 | 110 | 24 | 9.9 |

| DA35 | 127.5 | 189 | 130 | 32 | 15.3 |

| DA40 | 143 | 198 | 140 | 32 | 18 |

| DA45 | 148.5 | 221 | 155 | 38 | 24 |

| DA50 | 157.5 | 238 | 174 | 38 | 29.5 |

Diameter G = Casing diameter

Diameter D = Output major diameter

Diameter d1 = Input shaft diameter

(1) total length, depends on motor adapter

(2) maximum values, adjusted to customer motor

(3) average value, depending on motor adapter

Torque and Speed main data

| Size | Nominal output torque (1) [Nm] | Accel. / decel. torque [Nm] | Mean input speed (2) [rpm] | Max input speed [rpm] | |

|---|---|---|---|---|---|

| DA15 | (i 41, 59, 89, 119) | 258 | 613 | 5600 | 6150 |

| DA25 | (i 29) | 434 | 1029 | 3700 | 5050 |

| (i 41, 59, 89, 119) | 4200 | ||||

| DA35 | (i 29) | 584 | 1393 | 2960 | 4450 |

| (i 41, 59, 89, 119) | 821 | 1960 | 3300 | ||

| DA40 | (i 41, 59, 89) | 1047 | 2500 | 2900 | 3950 |

| (i 119) | 1054 | ||||

| DA45 | (i 29) | 1154 | 2756 | 2240 | 3350 |

| (i 41, 59, 89) | 1283 | 3062 | 2600 | ||

| (i 119) | 1291 | ||||

| DA50 | (i 41, 59, 89) | 1676 | 4000 | 2400 | 3150 |

| (i 119) | 1686 | ||||

(1) at input speed n1=1500 rpm

(2) at 50% ED

Output bearing capacity

| Size | Ratio i | Max. permissible bending moment [Nm] | Max. permissible axial load [N] |

| DA15 | all | 883 | 3924 |

| DA25 | all | 1660 | 5220 |

| DA35 | 29 | 1620 | 6530 |

| 41 - 119 | 2150 | ||

| DA40 | 41 | 2430 | 9000 |

| 59 - 119 | 2700 | ||

| DA45 | 29 - 41 | 3090 | 13000 |

| 59 - 119 | 3430 | ||

| DA50 | 41 | 3600 | 15000 |

| 59 - 119 | 4000 |

Available ratios

| Size | Ratios |

|---|---|

| DA15 | 41 / 59 / 89 / 119 |

| DA25 | 29 / 41 / 59 / 89 / 119 |

| DA35 | 29 / 41 / 59 / 89 / 119 |

| DA40 | 41 / 59 / 89 / 119 |

| DA45 | 29 / 41 / 59 / 89 / 119 |

| DA50 | 41 / 59 / 89 / 119 |

Above technical specifications are intended for rough preselection only.