Smartris Drive Compact

No bigger than a mouse: the new Smartris Drive Compact solution for compact AGV and AMR systems

Sumitomo Drive Technologies and Lafert Group show off new version of their complete solution for automated guided vehicle systems at Logimat 2023

Markt Indersdorf (Germany) / Venezia Noventa di Piave (Italy), March 23, 2023

Sumitomo Drive Technologies and Lafert Group will be jointly exhibiting a new version of their drive for applications in automated guided vehicle (AGV) systems at Logimat 2023 from April 25 to 27 in Stuttgart, Germany (Booth F45, Hall 6). The Smartris Drive Compact is a compact drive that is just a quarter of the size of the standard model.

The Smartris drive package combines three components: gearbox, servo motor and drive. The AGV solution is available in three sizes and different versions. When combined with the Eco-S series, the new Smartris Drive Compact can transport a total weight of up to 800 kg at a speed of up to 2.0 m/s.

"We developed Smartris Drive Compact to meet growing market demand for compact automated guided vehicle systems. The new drive is no bigger than a computer mouse, but delivers full functionality," says Christian Lochner, Product Manager Drive Systems at Sumitomo Drive Technologies.

The single-stage cyclo principle in the gearbox, the directly mounted servo motor and the in-wheel structure all help keep the Smartris especially compact. Compact AGVs can manoeuvre in tight spaces and narrow aisles, making them very flexible. They can be used in different environments, including production plants, warehouses, and distribution centres.

Energy efficiency through complete drive packages

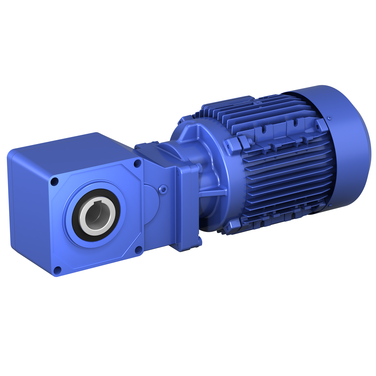

Visitors to the Sumitomo and Lafert booth will also learn how complete drive packages help to protect the environment and reduce costs. The booth will feature, as an example of energy efficiency in drives, the BBB-H IE5 drive package with a motor that complies with the IEC's IE5 ultra-premium energy efficiency class.

In the 0.75-4 kW power range, this drive solution combines a bevel helical gearbox, a Lafert IE5 PM synchronous motor, and an Invertek variable frequency drive (VFD). The individual components have been matched to achieve maximum energy savings and compactness in high-speed solutions such as baggage handling systems at airports, parcel sorting solutions in logistics hubs, and automated storage systems. Lubrication using a long-lasting grease ensures a long service life and reliability, regardless of the mounting direction. This will prevent oil leaks from contaminating the surroundings and so polluting the wider environment.