Reducer

ALTAX NEO Reducer

Utilizes the Cyclo Reducer mechanism \n Compact gearmotor with high shock resistance

Overview

- Compact reducer that utilizes our unique Cyclo Reducer mechanism.

- Allows for smooth, rolling contact with no teeth breakage, resulting in high-shock resistance.

- Attains a high reduction ratio with fewer reduction stages, resulting in high efficiency while simultaneously achieving a high reduction ratio.

- Concentric, and at the same time the smallest flange dimensions in the industry. There are no restrictions in the mounting direction, allowing you to design your application freely to meet your needs.

| Output Shaft | Solid shaft |

| Output Shaft Direction(s) | Any mounting direction |

| Mounting Style | Flange mount / Foot mount |

| Frame Size | 12 sizes |

| Reduction Ratio | 3:1 to 1 003:1 |

| Rated Torque | 1.56 to 458 Nm |

Facts

Long life

Unique gear mechanism ensures long life

Low noise

Unique structure enables quiet operation

Compact size

Unique design with high torque density

Product Features

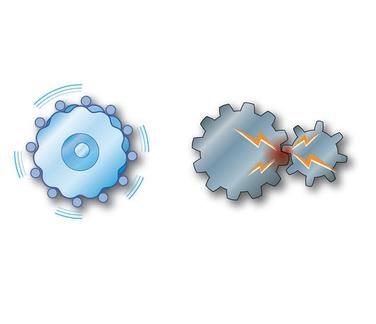

High Shock Resistance

Utilizes the Cyclo Reducer mechanism.

Combined with the unique circular-tooth profile for the internal gear, a smooth rolling contact is established without breakage, resulting in high-shock resistance.

Combined with the unique circular-tooth profile for the internal gear, a smooth rolling contact is established without breakage, resulting in high-shock resistance.

Low Noise

With the reduction mechanism firmly supported from both sides, along with its unique gear tooth count and gear mesh, low operational noise is achieved.

Smallest flange size in the industry (Flange type)

Unlike general gearmotors, the concentric shaft direction of both the motor and output shafts result in a compact flange.

High Shock Resistance

Altax NEO is a small-sized reducer that utilizes the Cyclo Reducer mechanism.

The Cyclo Speed Reducer features an ingenious mechanism that uses a cycloid disc with a unique smooth curve (epitrochoidal parallel curve), different from involute-tooth gear. This, combined with its unique circular tooth profile for the internal gear, allows for smooth rotating contact without tooth breakage, resulting in high-shock resistance.

It also achieves a high reduction ratio with fewer reduction stages, resulting in high efficiency while simultaneously achieving a high reduction ratio.